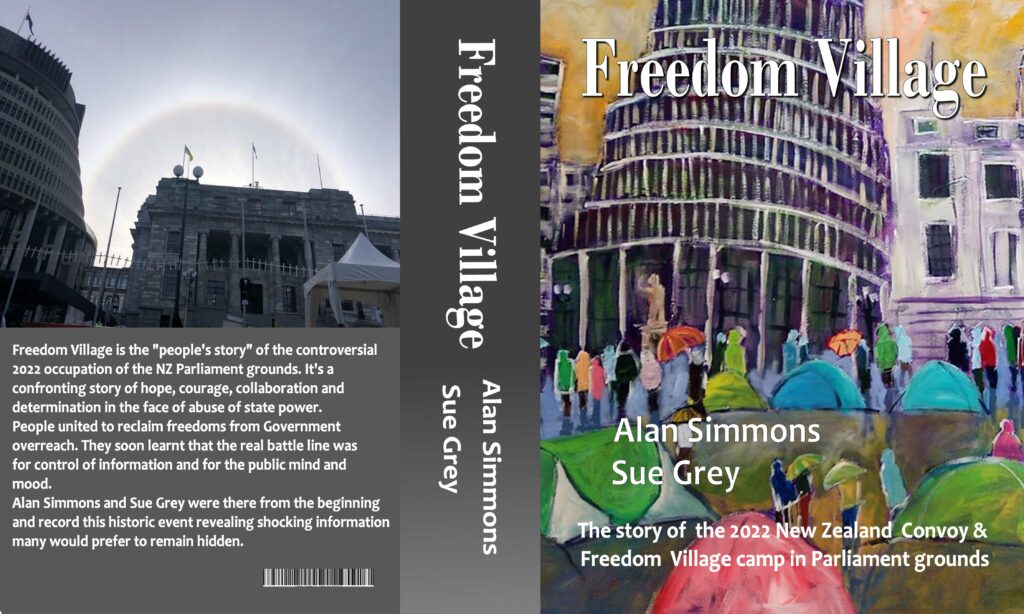

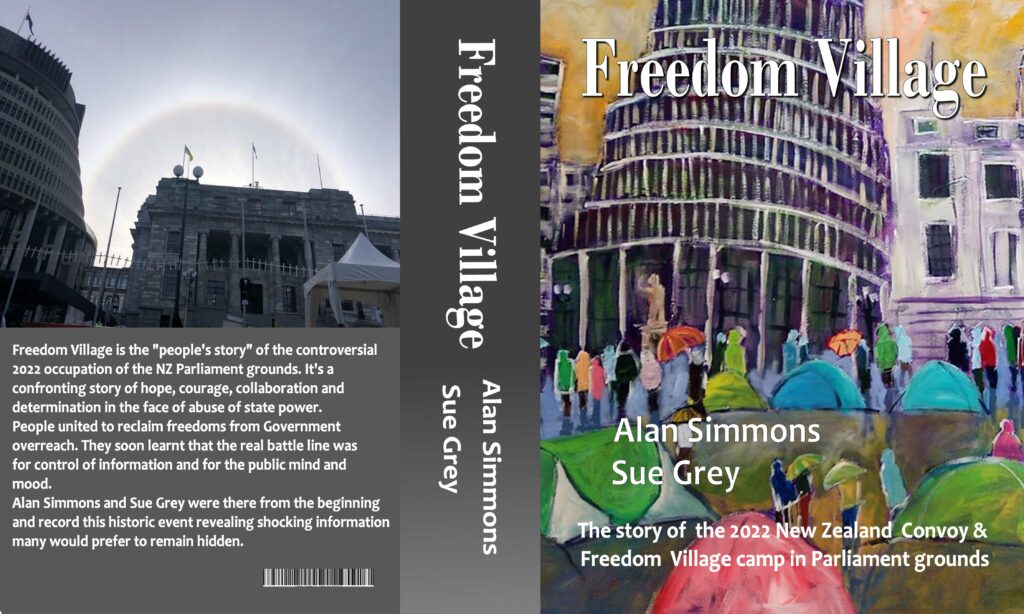

The Book Too Hot To Handle – Editors And Printers Said NO WAY!

This is one of the most important books of NZ history accurately detailing the events of February / March 2022.

The Book Too Hot To Handle – Editors And Printers Said NO WAY!

This is one of the most important books of NZ history accurately detailing the events of February / March 2022.